3D printing construction technologies have witnessed remarkable development in recent years, as 3D printing technology has emerged as one of the pioneering innovations that is revolutionizing this field. With the use of 3D printers, it has become possible to build complex and precise structures faster and at a lower cost compared to traditional methods, by converting digital models into realistic materials and structures. To keep pace with this development, Rakin Store offers innovative and diverse solutions in the field of 3D printing to meet your needs with the highest quality and the best prices.

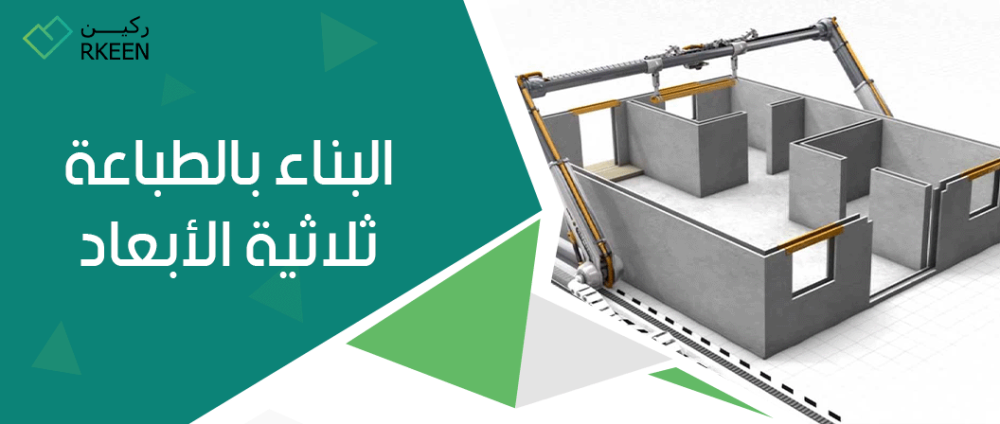

3D printing construction

3D printing is an innovative technology that uses digital printers to create architectural structures by adding layers of materials such as concrete or plastic. The process converts digital designs into physical structures, providing greater accuracy and efficiency compared to traditional construction. This technology helps reduce costs and time, reduces material waste, and provides complex architectural design capabilities, making it a sustainable and distinctive option for the future of construction.

Advantages of 3D printing construction

There are many advantages provided by building through 3D printing technology, and the most important advantages are the following:

Low costs

3D printing can significantly reduce costs, reducing the need for intensive labor, digital processes help reduce waste due to human error, and less expensive materials such as recycled concrete can also be used, making the final cost lower than traditional construction methods.

Speed of execution

3D printing greatly speeds up the construction process compared to traditional techniques, as printers can create structures in a very short time, as successive layers are built continuously without the need for waiting periods between operations, and therefore 3D printing construction contributes to reducing the time required to complete projects in general.

High precision design

3D printing offers extreme precision in design execution, enabling architects and engineers to create complex designs with fine detail. Digital control of printing also reduces measurement errors and ensures the structure is consistent with the original design, improving construction quality.

Environmental Sustainability

It also contributes to significantly reducing the environmental impact, because 3D printing uses materials more efficiently, which reduces waste, and the use of recyclable materials reduces waste.

Technologies used in 3D printing for construction

There are many techniques used in 3D printing construction, and they differ according to the materials used and the size of the structures required to be created. The most prominent techniques are:

Printing with concrete

This technology uses special printers that create structures using a special mix of concrete, where the concrete is pumped in layers on top of each other, allowing the formation of walls, cylinders and integrated architectural structures.

Printing with polymeric materials

This technology also uses polymeric materials such as plastic and PLA (polylactic acid) in printing, and is characterized by flexibility and accuracy in small details, and is usually used in projects that require complex designs or small-scale models.

metal printing

In this technique, a metal powder is used that is melted using a laser, and then the layers are built up gradually. This type of printing is used to build strong and precise structures.

Printing using clay or natural materials

This technology relies on printing using clay or similar natural materials, which can be shaped to provide sustainable architectural structures. Clay printing is an excellent option for projects that seek to reduce environmental impact.

Fiber printing

This technology relies on printing using fibers such as fiberglass or carbon fibers in concrete or polymer mixtures. This type of printing provides additional strength to buildings and reduces the weight of structures.

3D printing construction process steps

The construction process is done by 3D printing through a set of steps that are carried out as follows:

Digital design preparation

The architectural model is designed using CAD software and converted into an accurate 3D design that includes all engineering details.

Convert design to printable format

The design is converted to a format such as STL or G-code, and divided into virtual layers for subsequent printing.

Printer setup

The printer is prepared and the appropriate materials are loaded, with settings such as temperature and print speed adjusted.

Actual printing

The printer begins to build the structure gradually, adding successive layers of the chosen material according to the design.

Formatting and editing after printing

After printing, the structure is inspected and necessary adjustments such as shaping or adding insulation are made to achieve the final quality.

Project completion and installation

The structure is installed on site and other systems such as electricity and plumbing are installed after ensuring its quality.

Challenges of 3D printing construction technology

When adopting 3D printing construction technology, a set of challenges arise that need to be addressed, including:

- High initial cost, as advanced equipment and technology require large investments initially.

- Infrastructure, as the lack of necessary logistical support in some areas can hinder deployment.

- Training and qualification through the need to develop the skills of the workforce to ensure efficient use of technology.

- Legislation and regulation, as the absence of clear laws to regulate the sector may slow down the adoption process.

- Suitable materials: The need to develop building materials that can withstand hot desert climate conditions.

- Social acceptance, as some may prefer traditional methods of construction over modern methods.

Best 3D Printing Products from Rakeen Store

Whether you are a beginner or a professional, Rakin Store guarantees you a printing experience that combines innovation and mastery, so you can find out the best products available through it, which are as follows:

Unique Palace Model - AlUla

Get the unique palace model - AlUla , which is one of the most prominent heritage landmarks provided by Rukin store, as it reflects the precise details of one of the most important building models in 3D printing. The model is distinguished by its unique design that embodies the Saudi heritage and adds beauty to any place it is placed in. The model also blends with the decor to be an ideal addition, whether in homes or offices.

Features of the Alfred Palace model

- Reflects the Saudi heritage in a distinctive and elegant way.

- It has fine details that mimic the real palace.

- Suitable for use in distributions or as decoration anywhere.

- It makes a perfect gift for different occasions.

- It has a suitable size that does not require a large space to place it.

Diriyah Gate Model

Enjoy the best model of the Diriyah Gate , which is a distinctive addition to any decor. It embodies Saudi history and culture in an elegant and modern design. It also features wonderful architectural details and precise decorations. It is designed using 3D printing technology, making it a great choice for decorating different places such as offices, hotels and homes.

Features of the Diriyah model

- Adds a touch of Saudi history and culture.

- It comes with beautiful and delicate architectural details.

- It fits into any decor thanks to its elegant design.

- It comes in a perfect size to fit any space.

- Made of durable materials to ensure durability and retain original shape for a long time.

3D printing construction is a pioneering step towards a more innovative and efficient future in the construction industry, and Rakeen Store can be your ideal partner in obtaining high-quality 3D printing solutions for your needs, whether in architectural designs or heritage models.